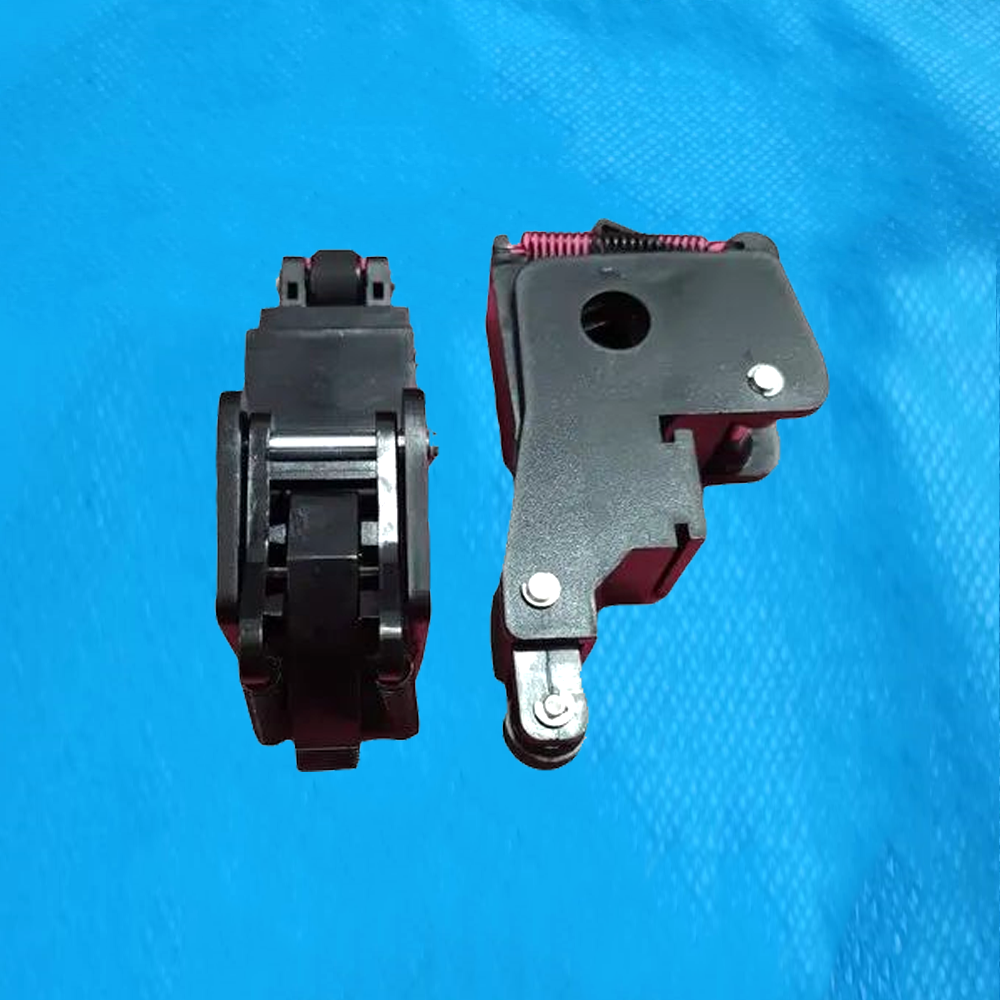

The cleaning and maintenance are also easily doable and not require many different cleaning liquids and fluids. The blades are made of tungsten and last quite a long depending on what material you're cutting with it. Your machine's cutting blades are designed to last a reasonably long amount of time (months to years depending on the manufacturer). This typically translates to about 500 to 1000 yards in material cut for vinyl, but it could be less if you're using a thicker, coarser material. We recommend an adhesive cleaner that is meant for vinyl cutters. Look for one that has the right solvent mixture as to not harm your equipment. Also, choose one that is mild in odour, non-hazardous, and biodegradable. If you have noticed a serious build-up of glue, use tweezers or even some adhesive removers to get rid of the build-up as soon as possible. To maintain your grit rollers, use the wire brush to scrub them lightly. Try going in a slow circular motion, which will get rid of paper scraps and more without causing any damage. Make sure that you do not interfere with any of the paint while doing this type of cleaning and removing of build-up. You must commit to cleaning the wheels about once a week to maintain things in good working order. This procedure will keep your wheels from getting coated in adhesive, which can cause you to have serious tracking problems. It is important to keep in mind to test on an inconspicuous area to determine if the cleaner will not remove any seals.